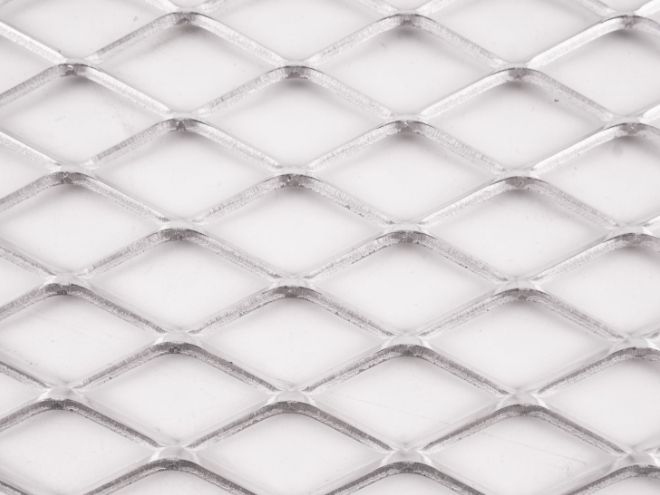

Standard expanded metal, also known as raised expanded metal, is produced by simultaneously slitting and stretching metal sheets or coils. It features a surface of raised diamond-shaped openings. In addition, raised strands form an angle to the original plane of the solid sheet, adding additional strength and rigidity. It also delivers great anti-skid performance. As a result, it has virtually endless applications including road fences, platforms and stair treads, machine guarding, etc.

We can supply a large assortment of standard expanded metal products made of high quality materials including carbon steel, galvanized steel and aluminum, to ensure the best performance and durability of the products. Besides, we can work with you to develop custom expanded metal solutions to fit your specific application through deep communication.

Carbon Steel

Galvanized Steel

Stainless Steel

Aluminum

Copper

Nickel

Titanium

Other Alloy

It is one of the most cost-effective metal materials with good rigidity and great durability. It is often galvanized or powered coated to enhance its corrosion resistance. It is widely used in support structures.

It is a type of steel that has been galvanized to enhance its corrosion resistance and anti-aging performance. It is widely used in various industrial applications including walkway gratings, stair treads, greenhouse benches, etc.

It has excellent corrosion resistant, impact resistant and fireproof characteristics. It has a bright, maintenance-free and easy to spray surface. It is widely used in various industrial and building decoration applications.

It features easy to form, high strength-to-weight ratio, great corrosion resistance and fire resistance. The surface is usually anodized or PVDF coated. It is an ideal material for architectural decoration applications.

It a safe and recyclable metal material with good softness, ductility, thermal and electrical conductivity. It is widely used in electrical appliances heat dissipation, Faraday cage, architectural decoration applications, etc.

It is a silvery-white metal material with good magnetic properties, high ductility and electrical conductivity. In addition, it is not easily oxidized in air and is often used to make special steels and other alloys, catalysts, etc.

It has a low density and the highest strength-to-weight ratio among all metallic elements. Besides, it has the highest corrosion resistance in seawater and chlorine. It is non-magnetic and has low thermal and electrical properties.

We also supply other alloy materials with higher rigidity, corrosion resistance, and other special properties for expanded metal production to suit to harsh working conditions and meet your special project requirements.

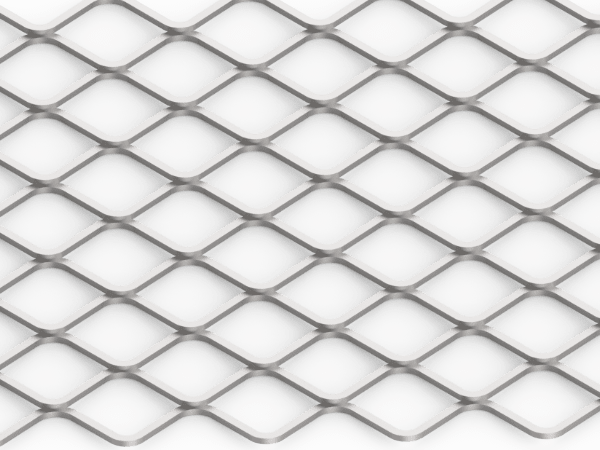

Diamond

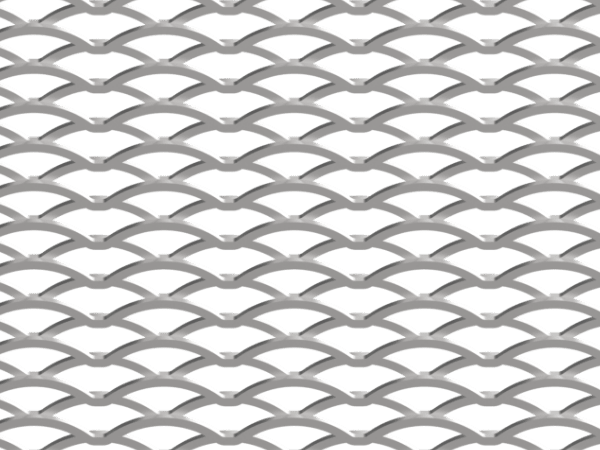

Fan-shaped

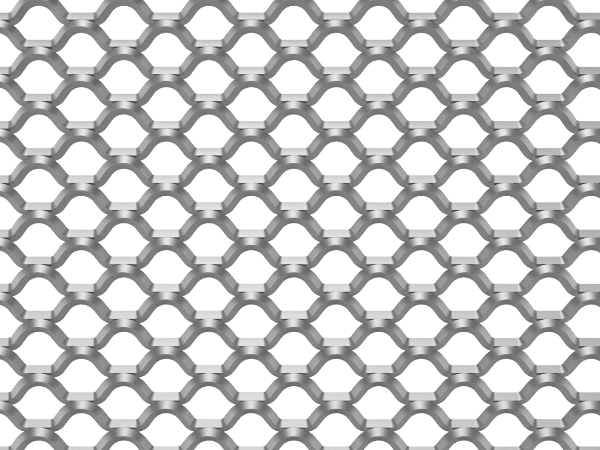

Round

Gothic

Hexagonal

Moreover, we can develop new moulds according to customers' requirements and supply expanded metal products with custom hole patterns.

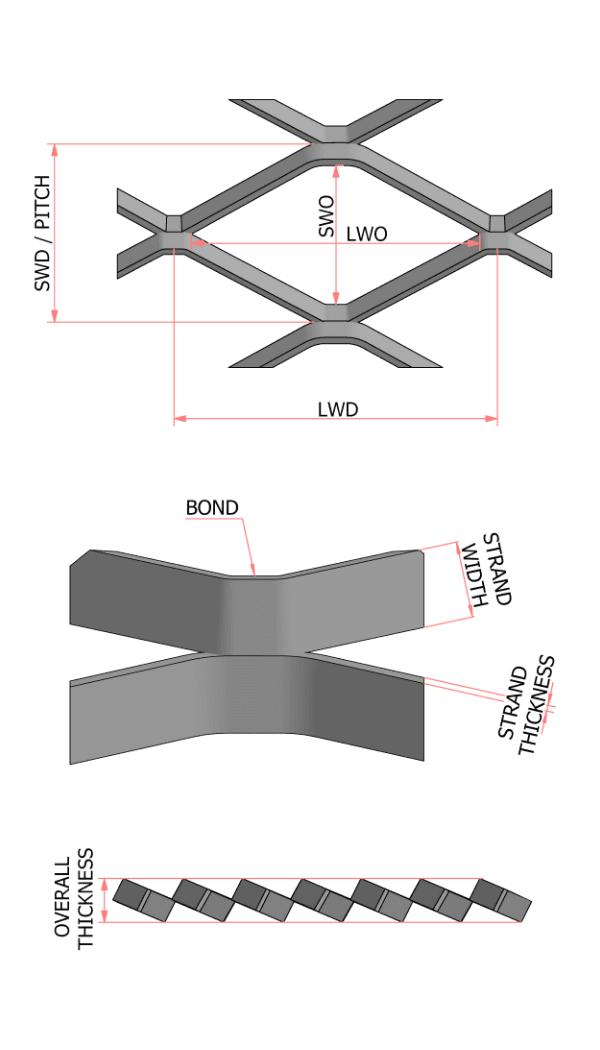

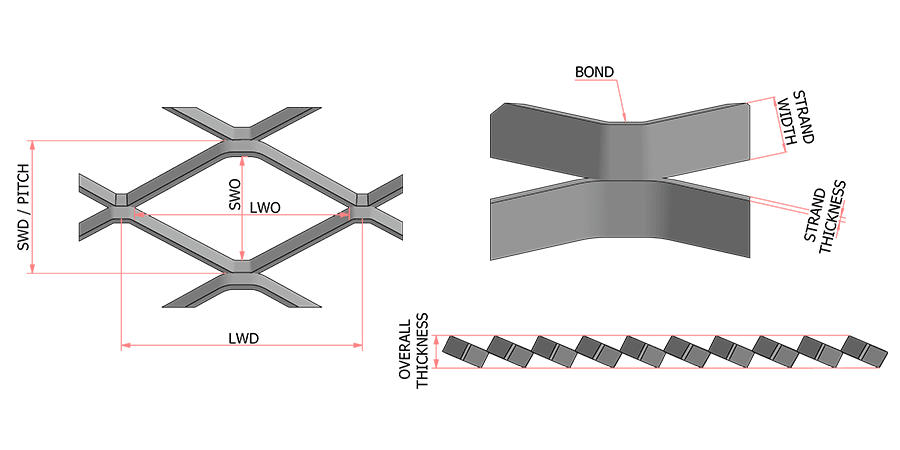

| Style | Minimum Thickness (inches)A | Nominal Weight in lbs./100 Sq. Ft.B |

Design Size (inches)C | Opening Size (inches)C | Strand Size (inches) | Overall Thickness (inches) | Open Area | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SWD | LWD | SWO | LWO | Width | Thickness | |||||||

| ¼"-#20 | 0.032 | 85 | 0.250 | 1.00 | 0.157 | 0.718 | 0.072 | 0.036 | 0.146 | 42% | ||

| ¼"-#18 | 0.042 | 113 | 0.250 | 1.00 | 0.146 | 0.718 | 0.072 | 0.048 | 0.151 | 42% | ||

| ½"-#20 | 0.032 | 42 | 0.500 | 1.20 | 0.407 | 0.938 | 0.072 | 0.036 | 0.146 | 71% | ||

| ½"-#18 | 0.042 | 69 | 0.500 | 1.20 | 0.382 | 0.938 | 0.088 | 0.048 | 0.180 | 65% | ||

| ½"-#16 | 0.053 | 85 | 0.500 | 1.20 | 0.372 | 0.938 | 0.087 | 0.060 | 0.183 | 65% | ||

| ½"-#13 | 0.083 | 141 | 0.500 | 1.20 | 0.337 | 0.938 | 0.096 | 0.090 | 0.212 | 62% | ||

| ¾"-#16 | 0.053 | 54 | 0.923 | 2.00 | 0.783 | 1.750 | 0.101 | 0.060 | 0.208 | 78% | ||

| ¾"-#13 | 0.083 | 77 | 0.923 | 2.00 | 0.760 | 1.688 | 0.096 | 0.090 | 0.212 | 79% | ||

| ¾"-#10 | 0.083 | 117 | 0.923 | 2.00 | 0.718 | 1.625 | 0.144 | 0.092 | 0.300 | 69% | ||

| ¾"-#9 | 0.127 | 178 | 0.923 | 2.00 | 0.675 | 1.562 | 0.150 | 0.134 | 0.329 | 67% | ||

| 1"-#16 | 0.053 | 43 | 1.00 | 2.40 | 0.872 | 2.062 | 0.087 | 0.060 | 0.183 | 83% | ||

| 1½"-#18 | 0.042 | 20 | 1.33 | 3.00 | 1.229 | 2.625 | 0.068 | 0.048 | 0.144 | 90% | ||

| 1½"-#16 | 0.053 | 40 | 1.33 | 3.00 | 1.184 | 2.625 | 0.108 | 0.060 | 0.221 | 84% | ||

| 1½"-#13 | 0.083 | 58 | 1.33 | 3.00 | 1.160 | 2.500 | 0.105 | 0.090 | 0.228 | 84% | ||

| 1½"-#10 | 0.083 | 76 | 1.33 | 3.00 | 1.132 | 2.500 | 0.138 | 0.090 | 0.288 | 79% | ||

| 1½"-#9 | 0.127 | 119 | 1.33 | 3.00 | 1.087 | 2.375 | 0.144 | 0.134 | 0.318 | 78% | ||

| 1½"-#6 | 0.184 | 247 | 1.33 | 3.00 | 0.979 | 2.313 | 0.203 | 0.198 | 0.452 | 69% | ||

| 2"-#10 | 0.083 | 65 | 1.85 | 4.00 | 1.630 | 3.438 | 0.164 | 0.090 | 0.335 | 82% | ||

| 2"-#9 | 0.127 | 88 | 1.85 | 4.00 | 1.603 | 3.375 | 0.149 | 0.134 | 0.327 | 84% | ||

| A The minimum thickness is absolute, not subject to minus variation. B A variation in weight per square ft. of ±10 % is permissible, based on the weight of any sheet or bundle. C A tolerance of ±10 % is permitted in dimensions, center to center. |

||||||||||||

| Style | Minimum Thickness (inches)A | Nominal Weight in lbs./100 Sq. Ft.B |

Design Size (inches)C | Opening Size (inches)C | Strand Size (inches) | Overall Thickness (inches) | Open Area | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SWD | LWD | SWO | LWO | Width | Thickness | |||||||

| ½"-#18 | 0.044 | 69 | 0.500 | 1.20 | 0.383 | 0.937 | 0.087 | 0.048 | 0.178 | 65% | ||

| ½"-#16 | 0.055 | 87 | 0.500 | 1.20 | 0.372 | 0.937 | 0.087 | 0.060 | 0.183 | 65% | ||

| ½"-#13 | 0.085 | 143 | 0.500 | 1.20 | 0.418 | 0.876 | 0.096 | 0.090 | 0.254 | 62% | ||

| ¾"-#18 | 0.044 | 46 | 0.923 | 2.00 | 0.790 | 1.750 | 0.106 | 0.048 | 0.212 | 77% | ||

| ¾"-#16 | 0.055 | 57 | 0.923 | 2.00 | 0.779 | 1.760 | 0.106 | 0.060 | 0.217 | 77% | ||

| ¾"-#13 | 0.085 | 87 | 0.923 | 2.00 | 0.751 | 1.687 | 0.107 | 0.090 | 0.232 | 77% | ||

| ¾"-#9 | 0.128 | 194 | 0.923 | 2.00 | 0.666 | 1.562 | 0.160 | 0.135 | 0.347 | 65% | ||

| 1½"-#16 | 0.055 | 43 | 1.33 | 3.00 | 1.179 | 2.750 | 0.115 | 0.060 | 0.234 | 83% | ||

| 1½"-#13 | 0.085 | 65 | 1.33 | 3.00 | 1.152 | 2.625 | 0.115 | 0.090 | 0.246 | 83% | ||

| 1½"-#9 | 0.128 | 130 | 1.33 | 3.00 | 1.077 | 2.500 | 0.155 | 0.135 | 0.338 | 77% | ||

| A The minimum thickness is absolute, not subject to minus variation. B A variation in weight per square ft. of ±10% is permissible, based on the weight of any sheet or bundle. C A tolerance of ±10% is permitted in dimensions, center to center. |

||||||||||||

| Style | Minimum Thickness (inches)A | Nominal Weight in lbs./100 Sq. Ft.B |

Design Size (inches)C | Opening Size (inches)C | Strand Size (inches) | Overall Thickness (inches) | Open Area | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SWD | LWD | SWO | LWO | Width | Thickness | |||||||

| ½"-.050 | 0.045 | 26 | 0.500 | 1.20 | 0.376 | 0.937 | 0.093 | 0.050 | 0.190 | 63% | ||

| ½"-.080 | 0.074 | 43 | 0.500 | 1.20 | 0.346 | 0.937 | 0.096 | 0.080 | 0.208 | 62% | ||

| ¾"-.050 | 0.045 | 17 | 0.923 | 2.00 | 0.786 | 1.750 | 0.109 | 0.050 | 0.219 | 76% | ||

| ¾"-.080 (Lt) | 0.074 | 31 | 0.923 | 2.00 | 0.741 | 1.680 | 0.129 | 0.080 | 0.268 | 72% | ||

| ¾"-.080(HVY) | 0.074 | 40 | 0.923 | 2.00 | 0.711 | 1.680 | 0.165 | 0.080 | 0.333 | 64% | ||

| ¾"-.125 | 0.118 | 64 | 0.923 | 2.00 | 0.667 | 1.680 | 0.169 | 0.125 | 0.359 | 63% | ||

| 1½"-.080 | 0.074 | 22 | 1.33 | 3.00 | 1.149 | 2.500 | 0.128 | 0.080 | 0.266 | 81% | ||

| 1½"-.125 | 0.118 | 43 | 1.33 | 3.00 | 1.080 | 2.500 | 0.162 | 0.125 | 0.346 | 76% | ||

| A The minimum thickness is absolute, not subject to minus variation. B A variation in weight per square ft. of ±10% is permissible, based on the weight of any sheet or bundle. C A tolerance of ±10% is permitted in dimensions, center to center. |

||||||||||||

It will help us to quote and deliver your order faster and more accurately if your would like to provide the following information.

Here you may roughly calculate the weight of the expanded metal.