Expanded metal grating is heavy-duty expanded metal produced by slitting and stretching thick steel plate (thickness ≥ 3 mm). Compared with standard expanded metal, expanded metal grating has a larger opening and a thicker strand, delivering good anti-skid performance and high load capacity. So, it is perfectly suitable for applications requiring high load capacity or high walk safety requirements, such as industrial platforms, stair treads, walkways and trailers.

Our expanded metal grating products come in a variety of sturdy and durable materials including carbon steel, galvanized steel, stainless steel, etc., to ensure it can maintain its best anti-skid performance and load capacity even working under the harshest environments.

Carbon Steel

Galvanized Steel

Aluminum

It is one of the most cost-effective metal materials with good rigidity and great durability. It is often galvanized or powered coated to enhance its corrosion resistance. It is widely used in support structures.

It is a type of steel that has been galvanized to enhance its corrosion resistance and anti-aging performance. It is widely used in various industrial applications including walkway gratings, stair treads, greenhouse benches, etc.

It features easy to form, high strength-to-weight ratio, great corrosion resistance and fire resistance. The surface is usually anodized or PVDF coated. It is an ideal material for architectural decoration applications.

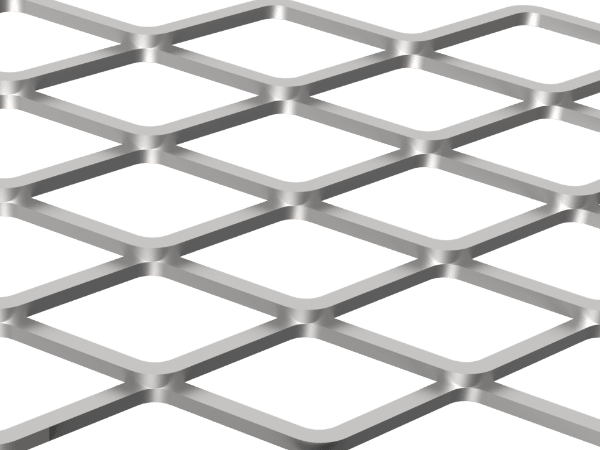

Diamond

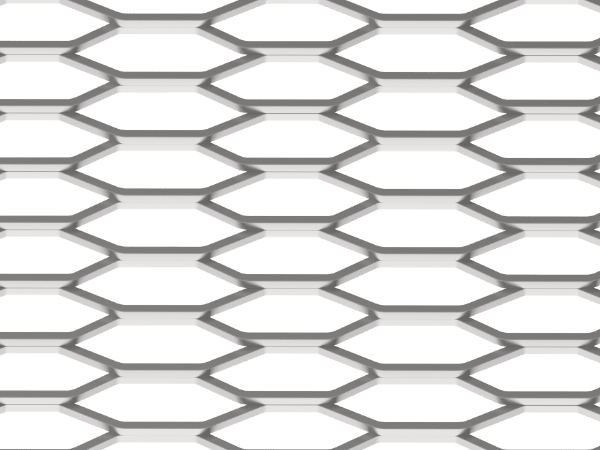

Hexagonal

| Style | Nominal Weight in lbs.Per Sq.Ft.A | Design Size (inches)B | Opening Size (inches)C | Strand Size (inches) | Overall Thickness (inches) | Open Area | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SWD | LWD | SWO | LWO | Width | Thickness | ||||||

| 2.0 Ib. | 2.00 | 1.33 | 5.33 | 1.000 | 3.60 | 0.235 | 0.135 | 0.460 | 77% | ||

| 3.0 Ib. | 3.00 | 1.33 | 5.33 | 0.940 | 3.44 | 0.264 | 0.183 | 0.540 | 60% | ||

| 3.14 Ib | 3.14 | 2.00 | 6.00 | 1.625 | 4.88 | 0.312 | 0.250 | 0.656 | 69% | ||

| 4.0 Ib | 4.00 | 1.33 | 5.33 | 0.940 | 3.44 | 0.300 | 0.215 | 0.618 | 55% | ||

| 4.27 Ib | 4.27 | 1.41 | 4.00 | 1.000 | 2.88 | 0.300 | 0.250 | 0.625 | 58% | ||

| 5.0 Ib | 5.00 | 1.33 | 5.33 | 0.813 | 3.38 | 0.331 | 0.250 | 0.655 | 50% | ||

| 6.25 Ib | 6.25 | 1.41 | 5.33 | 0.813 | 3.38 | 0.350 | 0.312 | 0.715 | 50% | ||

| 7.0 Ib | 7.00 | 1.41 | 5.33 | 0.813 | 3.38 | 0.391 | 0.318 | 0.740 | 45% | ||

| A A variation in weight per square ft. of ± 5% is permissible, based on the weight of any sheet or bundle. B A tolerance of ±5 % is permitted in dimensions, center to center. |

|||||||||||

| Style | Nominal Weight in lbs.Per Sq.Ft.A | Design Size (inches)B | Opening Size (inches)C | Strand Size (inches) | Overall Thickness (inches) | Open Area | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SWD | LWD | SWO | LWO | Width | Thickness | ||||||

| 3.3 Ib. | 3.32 | 2.00 | 6.0 | 1.625 | 4.88 | 0.312 | 0.250 | 0.656 | 69% | ||

| 4.5 Ib. | 4.25 | 1.41 | 4.0 | 1.000 | 2.88 | 0.300 | 0.250 | 0.625 | 58% | ||

| A A variation in weight per square ft. of ±5 % is permissible, based on the weight of any sheet or bundle. B A tolerance of ±5 % is permitted in dimensions, center to center. |

|||||||||||

| Style | Nominal Weight in lbs.Per Sq.Ft.A | Design Size (inches)B | Opening Size (inches)C | Strand Size (inches) | Overall Thickness (inches) | Open Area | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SWD | LWD | SWO | LWO | Width | Thickness | ||||||

| 2.0 Ib. | 2.0 | 1.33 | 5.33 | 0.940 | 3.44 | 0.387 | 0.250 | 0.730 | 48% | ||

| A A variation in weight per square ft. of ±5 % is permissible, based on the weight of any sheet or bundle. B A tolerance of ± 5% is permitted in dimensions, center to center. |

|||||||||||

| Style(lbs. per sq. ft) | - | 24-Inch Span | 36-Inch Span |

|---|---|---|---|

| 3.0# | Concentrated Load Capacity (lb./ft.) | 274 | 126 |

| Deflection Under Allowed Concentrated Load (in.) | 0.25 | 0.25 | |

| 3.14# | Concentrated Load Capacity (lb./ft.) | 340 | 117 |

| Deflection Under Allowed Concentrated Load (in.) | 0.25 | 0.25 | |

| 4.0# | Concentrated Load Capacity (lb./ft.) | 468 | 201 |

| Deflection Under Allowed Concentrated Load (in.) | 0.25 | 0.25 | |

| 4.27# | Concentrated Load Capacity (lb./ft.) | 419 | 196 |

| Deflection Under Allowed Concentrated Load (in.) | 0.25 | 0.25 | |

|

|||

| Style(lbs. per sq. ft) | - | 24-Inch Span | 36-Inch Span |

|---|---|---|---|

| 2.0# | Concentrated Load Capacity (lb./ft.) | 320 | 136 |

| Deflection Under Allowed Concentrated Load (in.) | 0.25 | 0.25 | |

|

|||

It will help us to quote and deliver your order faster and more accurately if your would like to provide the following information.

Here you may roughly calculate the weight of the expanded metal.