Safety is always a great concern in production, especially in the manufacturing industry. The equipment operation not only brings us economic benefits, but also put operators in a dangerous workplace. So, machine protection becomes very important.

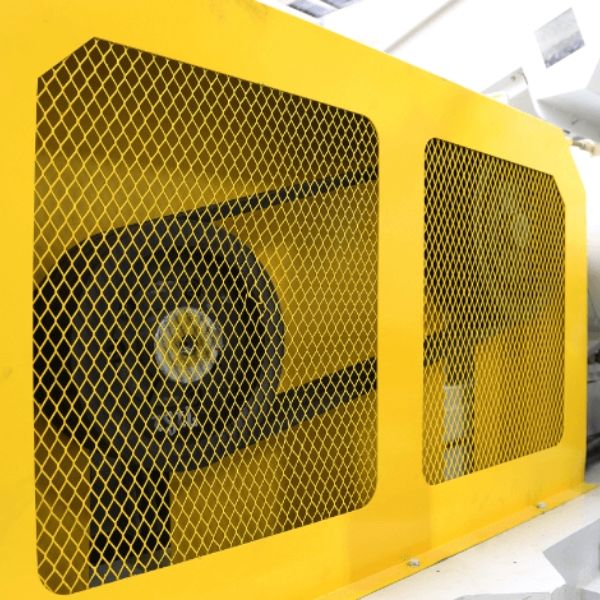

Our expanded metal machine guards are mainly used in machine perimeter protection and partial protection. The guard surface is generally electrostatic powder coated with alarming color, such as yellow and orange, aiming to reduce the occurrence of production accidents and ensure the personal safety of operators. All our expanded metal machine guards comply with OSHA (Occupational Safety and Health Administration) 1910.212 general requirements.

It is mostly used to protect flywheels, fan blades, belt pulleys, gears, connecting rods and other machine components that transmit energy to protect workers operating or working around the machinery. Besides, it also prevents clippings or other sharp objects from entering the machine, thus reducing the equipment abrasion and protecting the key assets of the enterprise.

Machine partial guards are generally made of flattened expanded metal. It features good rigidity, stable structure and its flat, smooth surface not only provides great safety protection, but also facilitates the operator accessing to the machine.

It is generally installed along the machines are prone to causing injuries, such as cutting machines, milling machines, forming rollers and calenders, to protect workers from chippings, flying chips or metal sparks generated during the machine operating. It usually consists of multiple pieces of expanded metal with frames, which is strong and easy to install and maintain.

Expanded metal not only plays an important role in machine guarding, but also is widely used in various outdoor equipment protection applications, such as outdoor air condensing unit protection cages, outdoor return passage machine cages and construction sit important item protection cages.

Our expanded metal outdoor machine cages feature sturdy structure, good anti-cut performance and can effectively prevent vandals from damaging and attacking the important parts of outdoor equipment. In addition, the machine cage after powder coated treatment can resist the erosion of rain, hail and other bad weathers, and enjoy a longer service life.

| Material | Opening Size (mm) | Strand (mm) | Open Area | ||

|---|---|---|---|---|---|

| SWD | LWD | Strand Thickness | Strand Width | ||

| Carbon steel, stainless steel | 22.58 | 50.8 | 3 | 3.12 | 72% |

| 40.64 | 85.73 | 3 | 3.18 | 84% | |

Pulley & belt protective cover

Drilling equipment protective cover

Outdoor air conditioning protective cover

Outdoor pipeline protective cover